Tel:+86 133 6177 9811

Fax:+86 0797 5712751

Email:sale02@miningshakingtable.com

Address:Guzhang Industrial Park,Shicheng County,Ganzhou City,Jiangxi Province,342700,China.

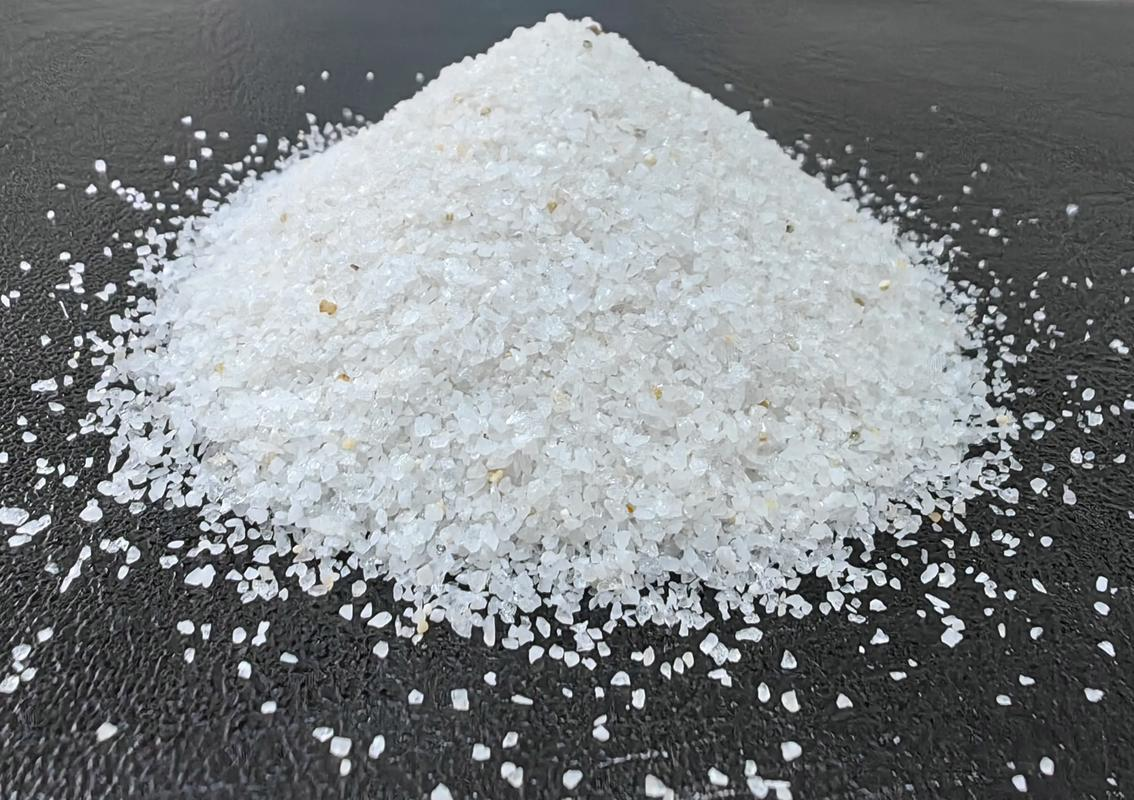

Quartz sand, also known as silica sand, is a common non-metallic mineral raw material. After beneficiation and purification, it can be made into high-purity quartz sand, which is widely used in industries such as glass, ceramics, metallurgy, casting, and refractory materials. So, what are the common methods for quartz sand beneficiation and purification?

I. Quartz Sand Water Washing and Classification Desliming Method

The SiO2 grade in quartz decreases as the quartz particle size decreases, while the grade of impurity minerals such as iron and aluminum increases. This phenomenon is particularly pronounced in quartz containing a large amount of clay minerals. Therefore, prior to quartz selection, water separation and classification desliming of quartz ore using equipment such as spiral scrubbers, drum screens, hydrocyclones, desliming buckets, and hydraulic classifiers is essential and effective. Water washing and classification desliming are long-standing and widely used pretreatment methods for ore selection, but their effectiveness in removing thin films of iron and adherent impurities on the quartz surface is not yet significant.

II. Quartz Sand Scrubbing Method

The scrubbing method primarily utilizes mechanical force and the abrasive forces between sand particles to remove thin film iron, adhesive, and clay-like impurities from the surface of the quartz sand. It also further breaks down unorganized mineral aggregates, and then undergoes classification to further purify the quartz sand. Currently, there are two main methods for quartz sand scrubbing: rod scrubbing and mechanical scrubbing. For mechanical scrubbing, the main factors affecting scrubbing effectiveness are the structural characteristics and configuration of the scrubbing machine, followed by process factors such as scrubbing time and scrubbing concentration. Research has shown that scrubbing concentrations between 50% and 60% are most effective for quartz sand ore, but this also increases the difficulty of quartz ore beneficiation and purification. In principle, the scrubbing time should be limited to achieving initial product quality requirements and should not be too long. Excessive scrubbing time increases equipment wear, energy consumption, and the cost of ore beneficiation and purification. For some quartz ores, mechanical scrubbing and erasing effects are not ideal. Rod grinding can be used for scrubbing. If necessary, chemicals can be added to increase the electric repulsion between the impurity minerals and the surface of the quartz particles, thereby enhancing the separation effect between the impurity minerals and the quartz particles.

III. Quartz Sand Magnetic Separation

Magnetic separation can minimize the removal of weakly magnetic impurities such as hematite, limonite, and biotite, including conjoined particles. High-intensity magnetic separation typically utilizes a wet high-intensity magnetic separator or a high-gradient magnetic separator. Generally speaking, quartz with impurities primarily composed of weakly magnetic impurities such as limonite, hematite, and biotite can be separated using a wet high-intensity magnetic separator at a magnetic field strength of 10,000 Oe or higher. For strongly magnetic minerals primarily composed of magnetite, a low-intensity or medium-intensity magnetic separator is more effective. Research has shown that the number of magnetic separations and magnetic field strength significantly influence the iron removal efficiency of magnetic separation. As the number of magnetic separations increases, the iron content gradually decreases. While a certain magnetic field strength can remove most of the iron, even significantly higher magnetic field strengths do not significantly change the iron removal rate. Furthermore, the finer the quartz sand particle size, the better the iron removal efficiency. This is because fine-grained quartz sand contains a higher concentration of iron impurities. When raw quartz sand contains a high concentration of impurities, scrubbing, desliming, and magnetic separation alone are insufficient to purify it into high-purity sand.

IV. Quartz Sand Flotation Method

Flotation primarily removes non-magnetic impurities such as feldspar and mica from quartz sand. Quartz sand flotation methods primarily include fluoride flotation and fluoride-free flotation. Fluoride flotation uses a cationic collector and hydrofluoric acid activator within an acidic pH range. Its disadvantage is that fluoride-containing wastewater poses a serious environmental risk and requires treatment before discharge. Fluoride-free flotation utilizes the structural differences between quartz and feldspar, rationally adjusting the ratio and dosage of a mixed anionic and cationic collector. By utilizing their different zeta potentials, the feldspar is preferentially floated out, achieving separation. Generally speaking, after scrubbing, desliming, magnetic separation, and flotation, the purity of quartz can reach 99.3%-99.9%, essentially meeting industrial sand requirements.

V. Quartz Sand Acid Leaching

Acid leaching utilizes the fact that quartz is insoluble in acid (except HF), while other impurity minerals can be dissolved by acid, thereby further purifying the quartz. Commonly used acids for acid leaching include sulfuric acid, hydrochloric acid, nitric acid, and hydrofluoric acid, and reducing agents include sulfurous acid and its salts. Research has found that these acids are effective in removing non-metallic impurities from quartz. However, the type and concentration of acid significantly influence the removal of different metallic impurities. It is generally believed that various dilute acids are effective for removing Fe and Al, while more concentrated sulfuric acid, aqua regia, or HF are most effective for removing Ti and Cr. A mixture of these acids is typically used for acid leaching to remove impurity minerals. Due to the dissolution of HF on quartz, the HF concentration is generally not allowed to exceed 10%. In addition to the acid concentration, the acid dosage, leaching time, temperature, and slurry agitation can also influence the quartz acid leaching effect. Controlling various factors during acid leaching should be based on the desired final quartz grade. Minimizing acid concentration, temperature, and dosage, as well as reducing leaching time, allows for quartz purification at lower beneficiation costs.

These are five common methods for quartz sand beneficiation and purification. Choosing the right method depends on a variety of factors, including the quartz sand's ore properties, beneficiation plant conditions, and investment budget. It's recommended to first understand the quartz sand itself and, based on beneficiation test reports, select a single or combined process to achieve optimal technical and economic benefits.